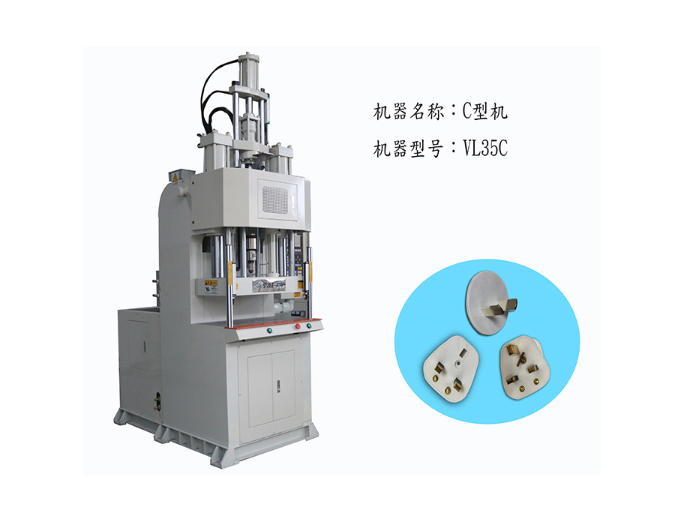

C型机

产品介绍

C型注塑机是一种立式锁模、卧式射胶的注塑机,其主要特点包括:

1. 立式直压锁模:C型注塑机采用直压式锁模方式,这种设计可以提供更高的锁模力和更稳定的模具闭合,适合于各种高精度的注塑成型。

2. 横式注射:注塑部分采用横式设计,可以提供更大的射胶量和更灵活的模具更换方式。

3. 无立柱:C型机最大的特点是没有立柱,这意味着操作人员可以更方便地进行模具的安装和调整,同时也便于自动化生产线的集成。

4. 三面开放:C型机的结构设计使得其在三个方向上都是开放的,这样可以方便模具的安装和产品的取出。

5. 中文/英文电控:C型机的控制系统支持中文和英文两种语言,方便不同国家和地区的用户操作。

6. 荧幕显示:注塑机配备有荧幕显示,可以实时监控注塑过程的各个参数,便于操作人员进行调整。

7. 双比例压力、流量油路控制:C型机的液压系统采用双比例压力和流量控制,这种设计可以实现更精确的注塑速度和压力控制。

8. 机构结构性强:C型机的机构设计紧凑,刚性好,能够承受高压和高速注射,适合于长时间的稳定生产。

9. 压力高、速度快:C型机的液压系统可以提供高压力和快速度的注射,适合于生产各种大型或复杂形状的塑料制品。

10. 多样化油路系统设计:C型机提供多种油路系统设计方案,如半闭、全闭、伺服或高速注塑等,以满足不同产品的注塑需求。

C型注塑机广泛应用于各种精密塑料制品的生产,如电子零件、电源插头、文具、体育用品、医疗用品等镶件射出成型作业。

C type injection molding machine is a kind of injection molding machine with vertical mold clamping and horizontal glue injection, its main features include:

1. Vertical Direct Pressure Mold Clamping: C-type injection molding machine adopts direct pressure mold clamping method, this design can provide higher clamping force and more stable mold closure, which is suitable for all kinds of high-precision injection molding.

2. Horizontal injection: The injection part adopts horizontal design, which can provide larger injection volume and more flexible mold replacement.

3. No column: The most important feature of the C-type machine is that there is no column, which means that the operator can install and adjust the mold more conveniently, and it also facilitates the integration of automated production lines.

4. Open in three directions: The structural design of the C-machine makes it open in three directions, which makes it easier for mold installation and product removal.

5. Chinese/English electronic control: The control system of C-model machine supports both Chinese and English languages, which is convenient for users from different countries and regions to operate.

6. screen display: the injection molding machine is equipped with a screen display, which can monitor each parameter of the injection process in real time, so that it is easy for the operator to make adjustments.

7. Dual proportional pressure and flow oil circuit control: the hydraulic system of C-model machine adopts dual proportional pressure and flow control, which is designed to realize more accurate injection speed and pressure control.

8. Strong mechanism structure: The mechanism design of C-model machine is compact and rigid, which can withstand high pressure and high speed injection and is suitable for long time stable production.

9. High pressure and high speed: The hydraulic system of C-model machine can provide high pressure and fast speed injection, which is suitable for producing all kinds of large or complex shape plastic products.

10. Diversified oil circuit system design: C-type machines provide a variety of oil circuit system design options, such as semi-closed, fully closed, servo or high-speed injection, to meet the injection needs of different products.

C-type injection molding machine is widely used in the production of various precision plastic products, such as electronic parts, power plugs, stationery, sporting goods, medical supplies and other inserts injection molding operations.